The right fit for your foundry

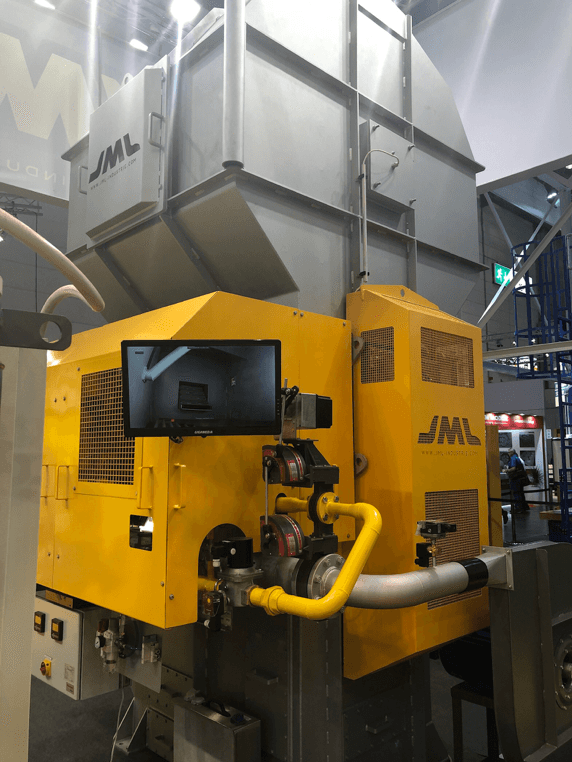

JML Industrie has over 40 years experience in producing high-quality equipment for foundries. In addition to designing, developing and installing industrial machinery, JML offers a repair and renovation service for your existing equipment for the majority of major manufacturers.

If you are interested to learn more about some of the previous projects we have worked on, we recommend that you read our case studies which include Le Creuset, Gatterman, PSA Peugeot Citroen and Fonderies de St Dizier.

Should you require a complete foundry rebuild, we are now in a position to deliver and install all of the equipment as well as work with you on the conception and design to maximise your productivity and the quality of your output.

We produce the following types of foundry equipment:

4.0 industrial equipment

The importance of Industry 4.0 within the foundry industry is growing. However, the reality is that many foundries are slowly introducing 4.0 machinery rather than upgrading all equipment. Our e-shooter, for example, offers foundries an Industry 4.0 compatible core making solution.

There are benefits, as well as draw backs to Industry 4.0 and we recognise the challenges. This is why, when we work with you to scope your requirements, we always consider the evolution of your equipment needs.

If you'd like to learn more about our view of Industry 4.0 and the challenges faced you can read our review here.

Some of the equipment we produce:

Equipment installed at Le Creuset

MUR SPACE Cooler

Dedusting filters

Thermal sand oven

Sand crusher

Thermal sand reclamation furnaces

Pneumatic conveyor

Vibrating machinery at Le Creuset

Sand silos

JML Installation

St Dizier siloes and hoppers

Dust silo

SPACE VR high intensity mixer

SPACE MUR

Fluidized bed sand cooler

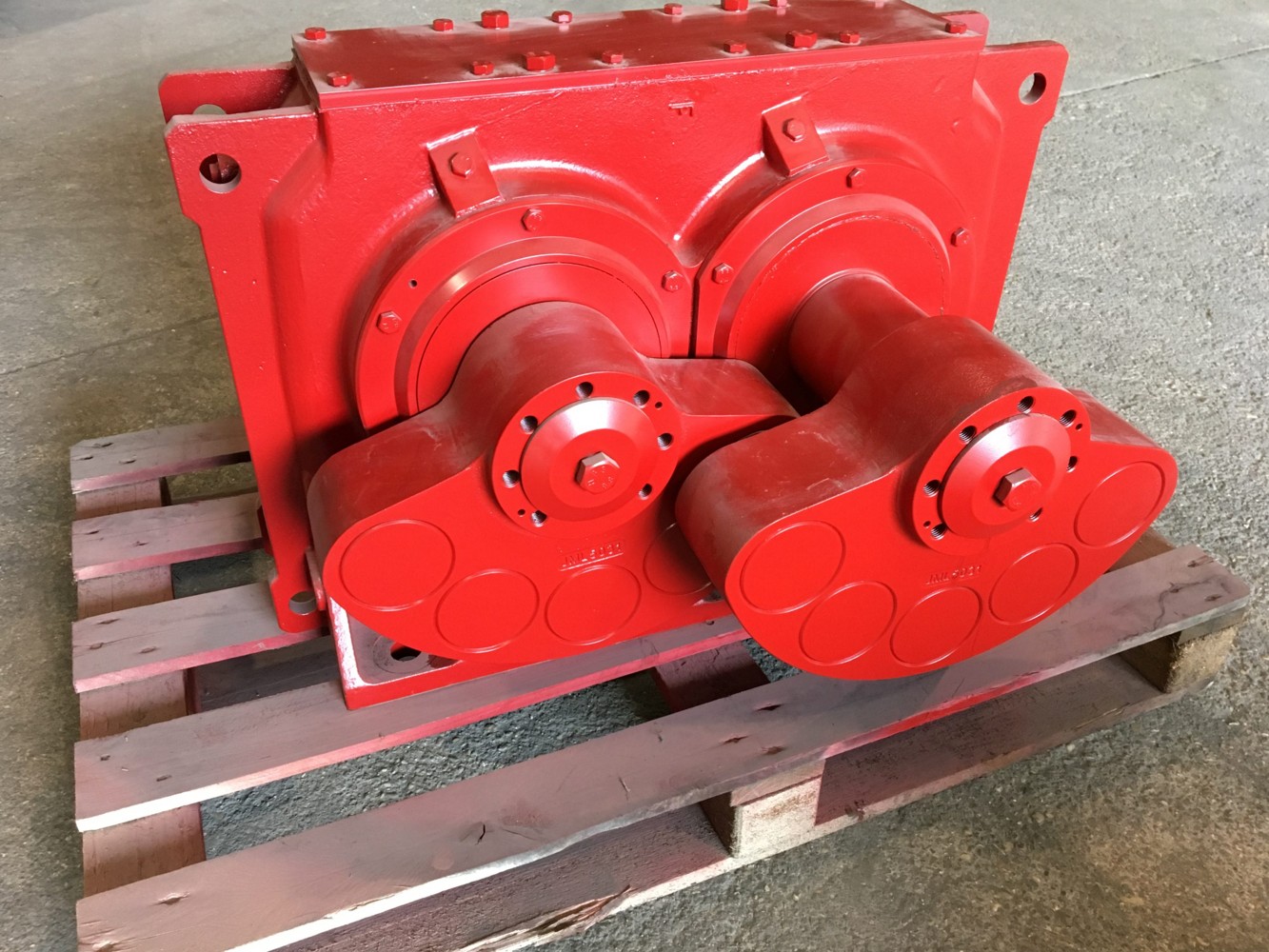

Exciter cell repair

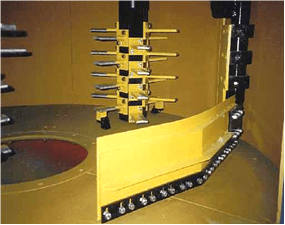

Belt conveyor for green sand preparation

Sand crusher

Rotary sieve

Stainless steel dust silo