JML were chosen as one of the core suppliers to help Le Creuset double the capacity of their Fresnoy le Grand site which was at operational capacity. It was already running 24/7 during the week with weekend hours maxed out. Because of the technical difficulty around the production of the enamel pieces the decision was made to keep the production in France.

Why we were selected

Amongst other factors, JML Industrie was selected for this project because:

- We are based in France and build our equipment here

- JML could fulfill 100% of the project requirements

- Maintenance recommendations were delivered as part of the scope

- The project would be delivered with a very tight timeframe

Project timeframe

The entire project, from brief to site launch, was completed in 18 months. This was despite a series of operational challenges including heavy snowfall during construction! The capacity of the Fresnoy Le Grand site was doubled due to the investment made and the configuration which was chosen. The site currently employs 650 people.

Our project timeframe for Le Creuset was as follows:

- 0- 6 months - Project scope and development

- 6 -16 months - Equipment build and delivery

- 16 - 18 months - Installation and testing

Project details

We were heavily involved in the planning of the project and the order in which the equipment would be set up. This meant we were able to ensure the optimal conditions in terms of safety for the installation and testing.

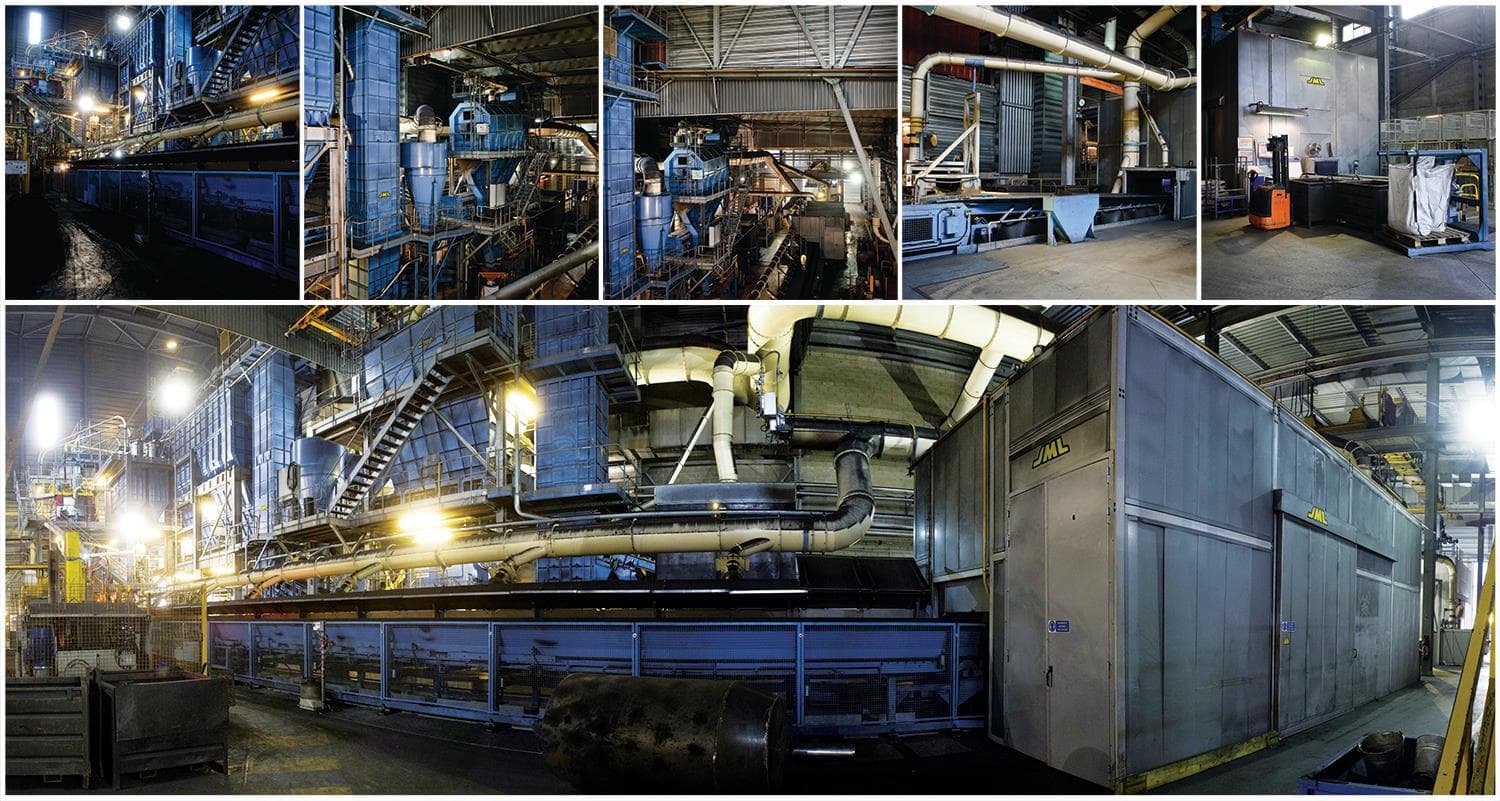

The new foundry included:

- DISA moulding machine with an output of 550 moulds per hour

- JML Industrie sand plant with 100 t/h capacity

- Induction ovens delivering 8 t/h

- A transfer unit

Project results

The factory has been in operation for a number of years now, and we continue to have an excellent relationship with Le Creuset. The reason that this project was such a success was thanks to the time invested at the start to correctly scope the needs of the expanded foundry.

Our commitment is always delivering the highest performing operations to our clients based on their requirements. This at times means we need to integrate the equipment of other suppliers. Our experience within the industry means not only that we can easily accommodate this, but that we can optimise the workflow for clients.

The feedback has been extremely positive and we know that our ability to quickly resolve problems to a high standard was much appreciated during the project.