JML Industrie has a number of divisions and teams. This has allowed each country to develop their key competencies and the result is the deep knowledge across the various divisions whilst JML Industrie is able to accompany you for all your equipment needs.

We are in a unique position to be able to advise you on vibrating machinery, sand preparation, core making, environmental solutions and automation. Our service division offers both equipment maintenance and part replacements. Currently we hold one of the largest replacement stocks of foundry parts in Europe and are proud to say that we have always been able to source the requested part.

JML France

All JML equipment is built at the French workshop in Vigne-aux-Bois. JML France is located at the original JML site and the production capacities have significantly expanded since its creation.

Equipment is produced here to ensure the highest standards in European fabrication of foundry equipment and to benefit from the decades of experience within the workshops.

Project gallery

JML Germany

All of the vibrating equipment is designed in Germany by the JML team. They work in close partnership with JML France who build it.

The vibrating machinery branch operates in Germany to benefit from the engineering expertise that comes from exceptional experience within the country for foundry equipment.

Project gallery

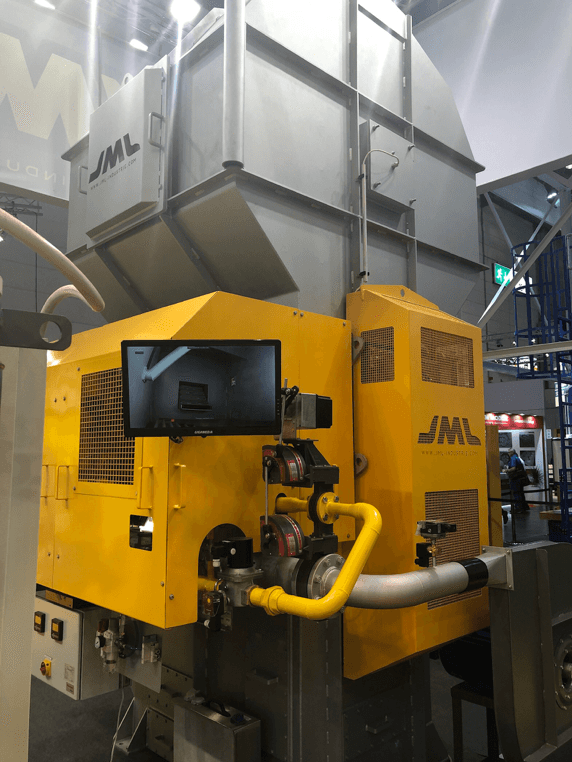

JML Italy

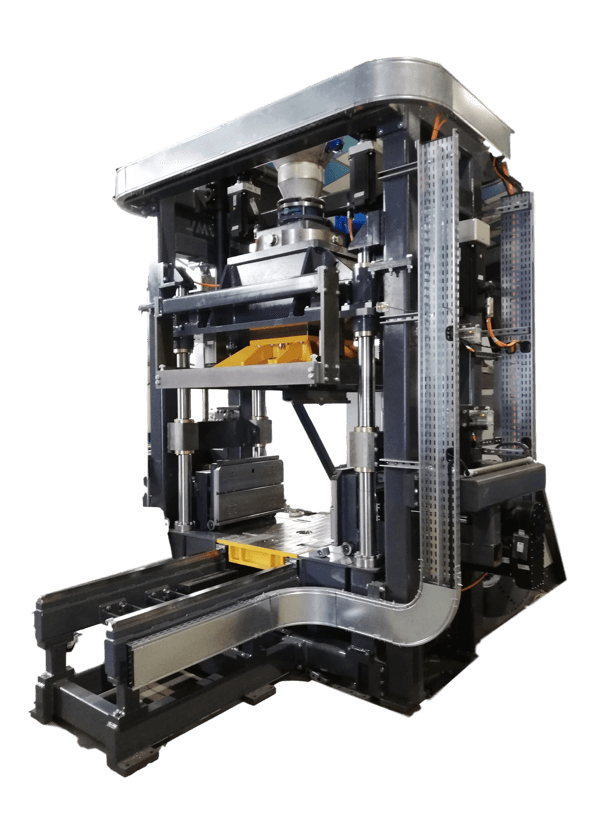

The Italian division is the most recent addition to JML Industrie. The branch leads our environmental division as well as equipment innovations. The most recent example is the JML e-shooter which is a fully electric core shooting machine.

Project gallery

SPACE

Based in Italy, SPACE is internationally recognised for their design and construction of sand cooling and preparation equipment for green sand. SPACE has developed a unique methodology to achieve the highest quality sand for the lowest price consumption of raw materials. SPACE and their team integrated into JML Italy in 2020.

Project gallery

JML Automation

The newest addition to the JML group is the automation division. Composed of a young team, JML Automation allows us to answer to our customers' requests for the control and regulation of the foundry equipment proposed by JML.

Subcontracting in this field posed increasing risks for clients. We are pleased to now have the management and control of all the stages of our foundry equipment. Moreover, as robotics are increasingly entering the manufacturing lines we offer, we are developing a high skills level in this field to meet the needs of the market and our clients.