Benefits

- Improved energy efficiency

- Reduced maintenance

- Silent and clean

- Environmentally friendly

- No pit required for installation

- Fast clean time

Core features

- Patented machine

- 100% electric

- Industry 4.0 ready

- Hydraulic oil free

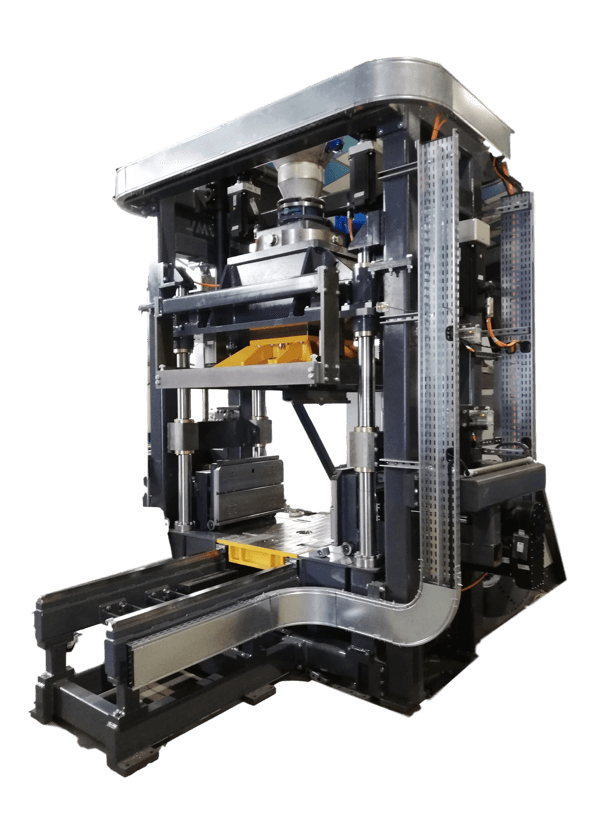

- Horizontal or vertical use

- Split core boxes

- Closed core box

- No movement in shooting and gassing

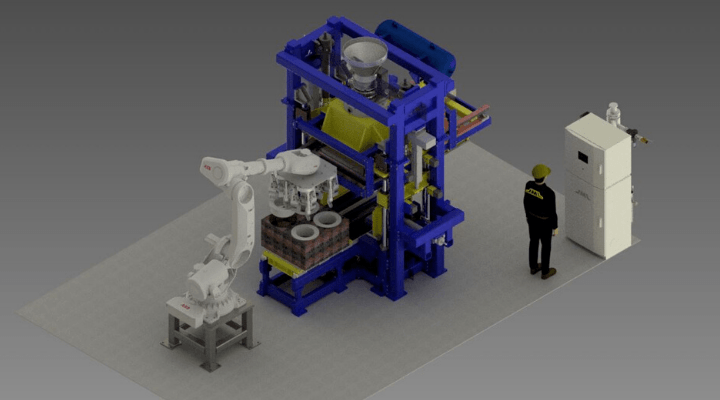

Description

The JML e-shooter, a patented machine, is a fully connected and 100% electric Industry 4.0 compatible machine. Operational costs are significantly lower thanks to the energy savings, removal of insurance fees and reduced maintenance staff, when compared to conventional machines.

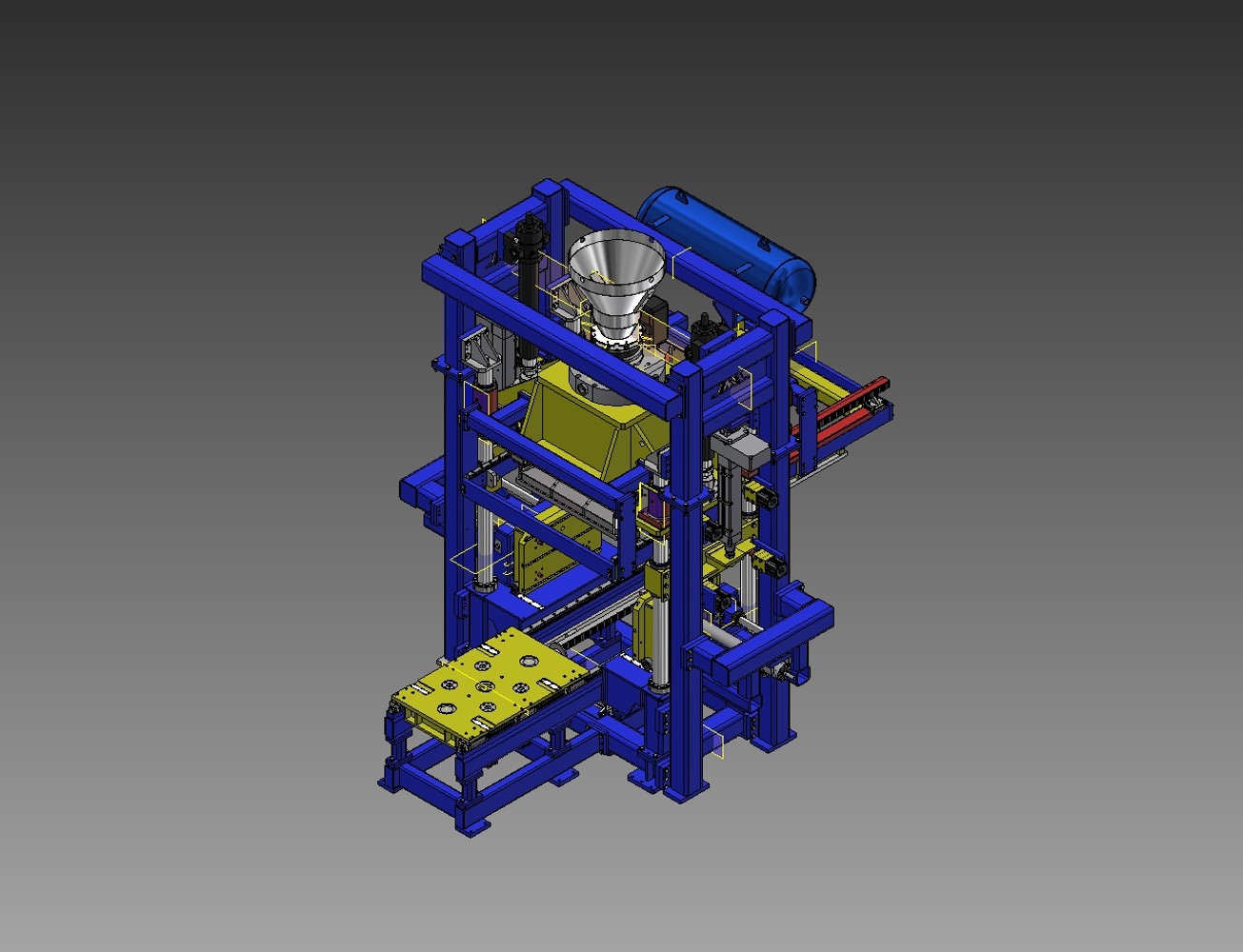

The e-shooter is based on a lower static structure with a movable shooting and gassing head. The machine has been designed to provide better access for both cleaning and maintenance. Cleaning time is further reduced due to the absence of a shooting cartridge.

-30% energy saving

2,397 kWh/a are saved using the 4EE solution. This can amount to 383 €/a of savings (404g/kWh, 0.16 €/kWh) and a carbon dioxide reduction of 1 t/a.

E-shooter performance

- 16-second cycle time (based on split core boxes)

- 98% machine efficiency

- 98 production cycles per hour

- 2,058 estimated cycles per day (based on a cycle process of 20 secs)

- 10,290 total cores produced per day (based on 5 cavities core box)

- 10,080 viable cores produced per day (based on 2% cores’ scrap)

Technical drawings

Technical specs

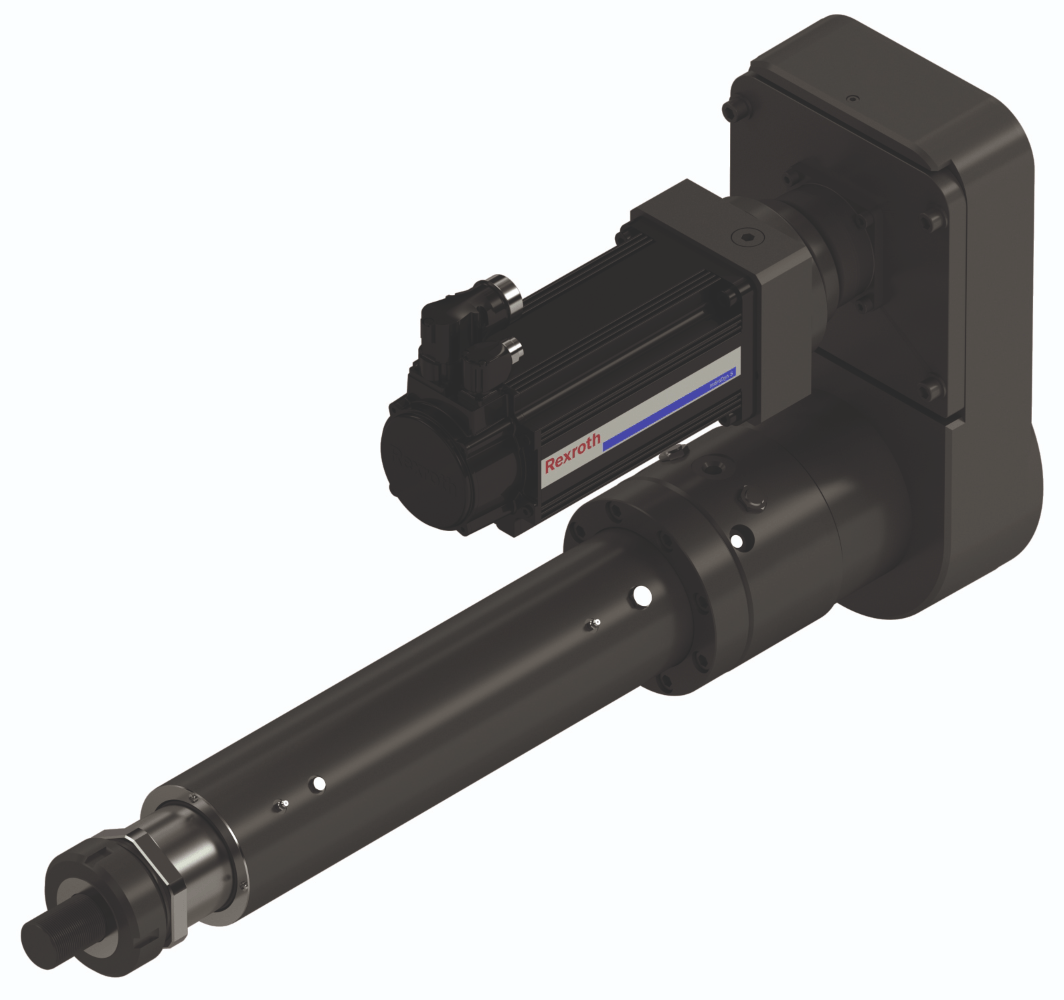

Indradrive energy benefit

The E-shooter uses a Rexroth 4EE electric solution. When compared to a standard hydraulic power unit with vane pump for pressure supply, this machine requires less cooling power and reduces noise when in operation.

Technical data

Installed electrical power – 40 Kw

Electrical Power requirement during cycle – 12 Kw

Sand Hopper capacity – 100 L

Maximum core weight – 60 Kg

H core box maximum dimensions – 880 x 880 x750 mm

V core box maximum dimensions – 880 x 880 x750 mm

Shooting and gassing maximum area – 800 x 800 mm

Closing table maximum force – 26.500 Kgf

Vertical core box dry cycle time -19 sec

Horizontal core box dry cycle time – 16 sec

Maximum noise level – 75 db(A)

Gas extraction requirements – 3.000 m³/h

Installed air supply pressure (dry air) – 6 Bar

Estimated Air consumption at 6 bars- 70 m³/h (including shooting blowing and spraying)

Video

Receive the full technical specification and equipment details for Electric core shooter as a PDF document direct to your inbox. Simply provide your email and you will receive the download shortly.