Replacement parts

Fast and quality replacement parts for your foundry equipment

Benefits

- Specialists in replacement parts for foundries

- Wide-ranging partner list and access to many rare parts

- On-site maintenance and repair resulting in rapid turnaround times

- Rapid delivery

- Quality parts from trusted suppliers

- Represent KLEIN Anlagenbau AG and NEDERMAN MikroPul GmbH in France

Parts available

Due to the range of parts we can source it is impossible to list them all. However, the list below shosw some of these parts we replace regularly to help you get your machinery up and running again:

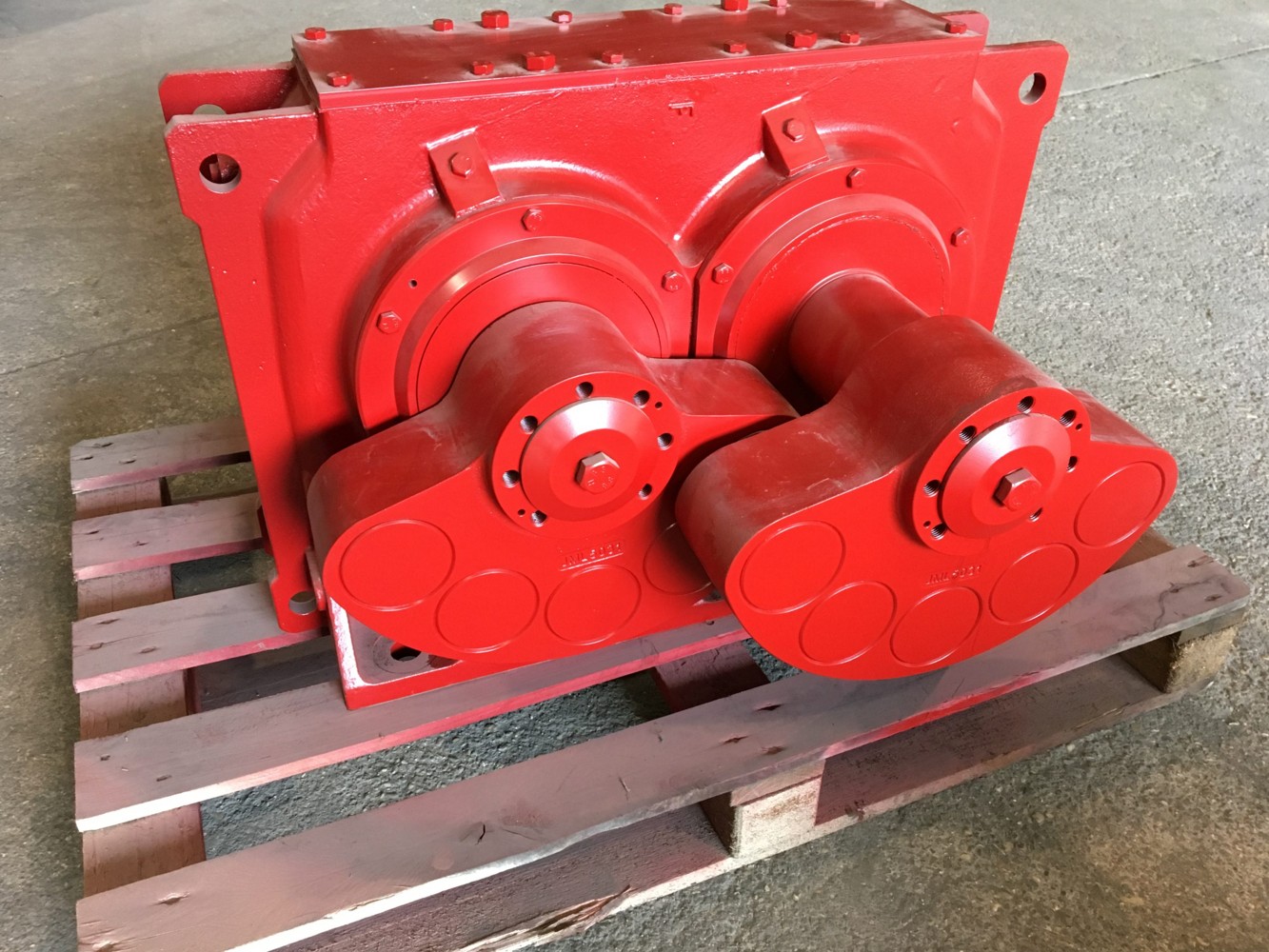

- Conveyor system, handling and storage

Rollers, belts, elevator belts and screws - Pneumatic transportation installations

Pulsair accessories, anti-abrasion ducts (basalt elbow), air assist - Vibrating machinery parts

Exciter, cell, crank rod, spring, cardan shaft, wear plate, unbalance motor - Core machinery

Firing valve, roller, seals - SPACE Equipment

Pale, shaft of pale, probe - Dedusting installations

Filter pocket, pocket support, cleaning - Sand mixing equipment

Mixing vat, pale, mixer

Description

Our replacement parts service ideal for both ferrous and non-ferrous foundries as well as sand plants. We are able to extend our service to other fields of activity thanks to our wide range of parts and experienced team.

With more than 40 years of experience, we know where to look to find rare spare parts. We’ve been working with trusted partners for years ensuring not only the quality of the parts but rapid delivery. In addition, we have an on-site manufacturing workshop and a dedicated machining partner to respond to emergencies. Meaning the right part solution is never far from reach.

Clients

- Groupe PSA

- La Fonte Ardennaise

- Le Creuset

- Staub

- Manoir Outreau

- LE BELIER Hongrie

- Proferro picanol group

- Lecomte

- Funosa

- Lisie Katy

- BREMBO

- Rio Tinto

- SNVI

- AIA

- Teksid

How we work

1. Consultation

JML Industrie, under the lead of Nathalie Pageot, will help you assess your equipment needs. The renovation team includes a full technical team, a design & development office, and our expert fitters.

2. Technical audit if part of a larger project

Our aim with the technical audit is to find the fastest and most cost-effective approach for the replacement part. We can often suggest modifications or part upgrades which will help simply maintenance activity or reduce future intervention costs.

3. Order

The delivery time frame depends on the availability of the parts. However, due to the large volume of replacement parts available on-site, we are often able to respond to requests more quickly than other providers.

4. Delivery

Your order is tracked so you will always be updated with its progress and we are available to answer any questions you might have.