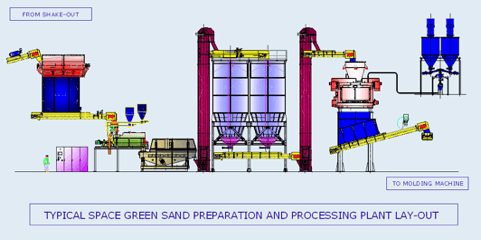

How the SPACE concept for the treatment of return sand in green sand moulding plants delivers the best characteristics of sand with the least consumptions.

SPACE, now part of JML Industrie, is specialized in the treatment of moulding green sand and has built its excellent reputation thanks to the innovative SPACE SYSTEM.

How does the SPACE system work for treatment of return sand?

Step One

Premixer to homogenize the return sand, by batching water and additions.

Step Two

Fluid bed cooler, where the values of moisture and temperature are brought to the required parameters, in very strict limits.

Step Three

The treated return sand is introduced into the storage silos. Here the bentonite is activated slowly and in a natural way.

Step Four

Intensive mixer where it takes place the final adjustment of the moulding sand, also by mean of an accurate automatic management system.

Advantages of the SPACE system

The latest studies on SPACE installations at some of our most important customers have shown:

- Reduced consumption of additives between 10% and 16%

- Increase in the efficiency of the mixer between 65% and 85%

- Reduction of defective/broken moulds between 5% and 10%

- Improvement of the green sand properties, reduction of the scraps and lower costs for shot blasting and casting fettling.

Why choose the SPACE system?

Because the equipment proposed provides the most innovative and competitive solution in the world market.

The SPACE system has the following benefits:

- High quality instruments of measuring and control

- Constructive quality of the machine

- Low maintenance requirements

- Negligible consumption of space parts