How have green sand molding requirements changed over the years?

Over the past 20 years, the requirement of quality, in particular but not only, by users in the automotive sector, are the source of modernizing the structures of technological readiness of existing green sand plants. The quality and characteristics of molding sand as it was conceived in the recent past, now is not acceptable.

The cadences of the installations of green sand molding, both type flaskless vertical and/or horizontal separation, as well as those using the flask molding, can be managed only if the technical characteristics of the green sand are kept in accordance with the programmed values within limits very tight.

In short, it must always comply with the necessary values in the green sand used for the molding, even in the presence of a great variability of the different characteristics in the return sand from the shakeout.

At the same time, one of the consequences of the recent crisis was that, to alleviate the drastic reduction in the value of sales, general business and foundries in particular, have devoted their efforts, with a production substantially reduced in order to maintain where possible, the necessary margin of profit by reducing production costs.

Said target can be achieved mainly by reducing the consumption of raw materials and minimizing the number of defective castings or scrap.

Space, in response to these needs, collaborating with some of its traditional customers, has developed an important research work on the optimization of equipment and controls achieving, without large investments, very positive results.

Optimal molding sand preparation

A good molding sand, where it is intended to feed a vertical flaskless molding line, in our experience should appear with the following values:

| Compressive strength | gr/cm2 | 2,300 ± 50 |

| Shear strength | gr/cm2 | 550 ± 25 |

| Moisture | % | 3.2 ± 0.1 |

| Compatibility | % | 40 ± 2 |

| Permeability | gr/cm2/m | 100 ± 5 |

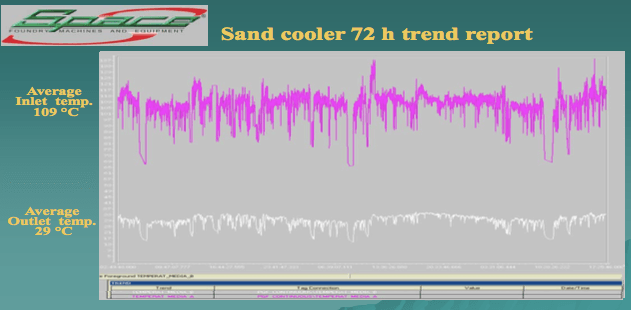

The data above shows the behaviour of the temperature of the green sand before and after treatment with an installation of MU + TVR Space 120 T/h, installed in a foundry which produces exclusively for an important automotive industry.

It is obvious the excessively uneven temperature behaviour at the inlet with values varying between 65÷125 ° C while the output values found are stable between 25÷35 ° C.

A document, prepared by one of our customers, from which we have the consent and permission for its disclosure, provides information of a confidential nature relating to the production and confirms the remarkable economy seen after the investment made with the installation of the system Space, as well as the improved quality of castings and reduced casting scrap.

Effective treatment of return sand

Regardless of the type of the installation of molding, the return sand will always suffer for substantial changes in the values of flow rate, temperature and residual moisture.

For years, the continuing need to improve the quality of green molding sand, always in coincidence with the increase of the production of the plant, it is taken for granted the need to optimize both equipment and facilities for the correct preparation of molding green sand.

In the market appeared coolers, pre-coolers, mixers, vibrating fluid bed coolers, cooling mixers … etc. all controlled by more or less complex control equipment.

You could say that to the market appeared more manufacturers than ideas.

So you could say in a more direct way and, as always happens in all areas, that from an idea many copies were created.

Introduction of additives in the pre-mixer

The technical department of studies and projects Space, with more than 49 years of experience in the preparation of the green molding sand, but above all, thanks to the collaboration of our most demanding customers, has developed an innovative technological process. A process started and already experienced for years in many installations. This process ensures the management and control best suited to the regeneration and development of for green molding sand.

Below we provide a summary of the experience gained through innovation and checked step by step in the practical exercise of the treatment of the molding sand.

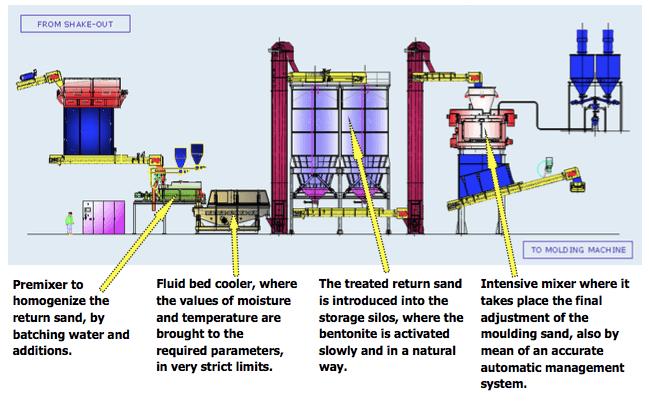

Step Two: Both the fines collected by the filter, rich in bentonite, as well as an important part of the total of bentonite and water, may be introduced in the pre-mixer together with the return sand, so as to promote the subsequent activation of the bentonite in the storage silos. The introduction in the pre-mixer of a preliminary amount of additives and the fines (up to 60%÷70% of total) allows to better prepare the molding sand, with a considerable saving of energy and raw material consumption, as well as improving the equipment performance

Step Three: The treated return sand is introduced into the Storage silos in which the bentonite is activated slowly and in a natural way.

Managing hot and dry return sand

It is desirable to reduce the temperature at least to 34÷38 °C and humidity values about 2÷2,3%. The temperature and humidity of the return sand can vary within a wide range of values, as well as the flow rate or capacity of the preparation plant.

In order to decide, for the most accurate corrective actions, it is essential to obtain the instantaneous values of temperature, humidity and flow rate of the system.

A temperature probe PT 100, located and protected in a very thin support, not to suffering from excessive thermal inertia, measures the temperature of the return sand.

A capacitive radiofrequency probe SPACE “PGF” provide a continuous measurement of moisture in the return sand.

A system of continuous weighing, applied on the conveyor belt, grant a continuous measurement of the return sand weight.

A set of temperature sensors and moisture, installed at the outlet of the cooler, ensure the measuring of the sand temperature and the humidity.

All probes, through an analogue to digital conversion circuit, are connected to a PLC. A program developed and adapted specifically for each application ensures a fully automatic operation of plants. A feedback system, based on a PID algorithm, ensures the constant maintenance of the characteristics of programmed values within narrow limits of variability.

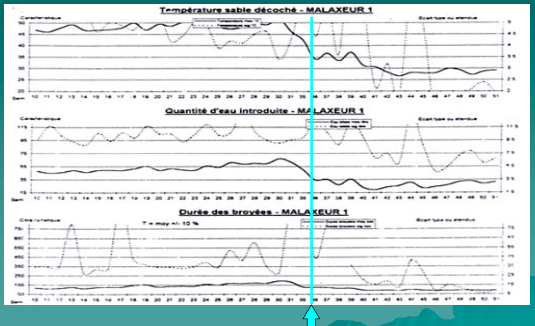

The above graphs display the parameters before and after (see blue arrow indicates the date before / after) of an installation System Space:

- The evolution of the temperature of the sand at the beginning of the mixing cycle.

- The amount of water added in each cycle.

- The required mixing time after introducing water into the mixer

The data correspond to a foundry, equipped with a green sand molding plant with two mixers, which was originally not equipped with premixing and cooling system.

It is evident that the lowering of the temperature from 55/65 ° C at levels of 25/30 ° C, together with further optimization of the moisture of the sand introduced into the mixer, has allowed a considerable reduction of the water introduced by the 40/65 litres to 20/30 litres and a consequent reduction of the total cycle time by a maximum of 180 seconds to about 100 seconds.

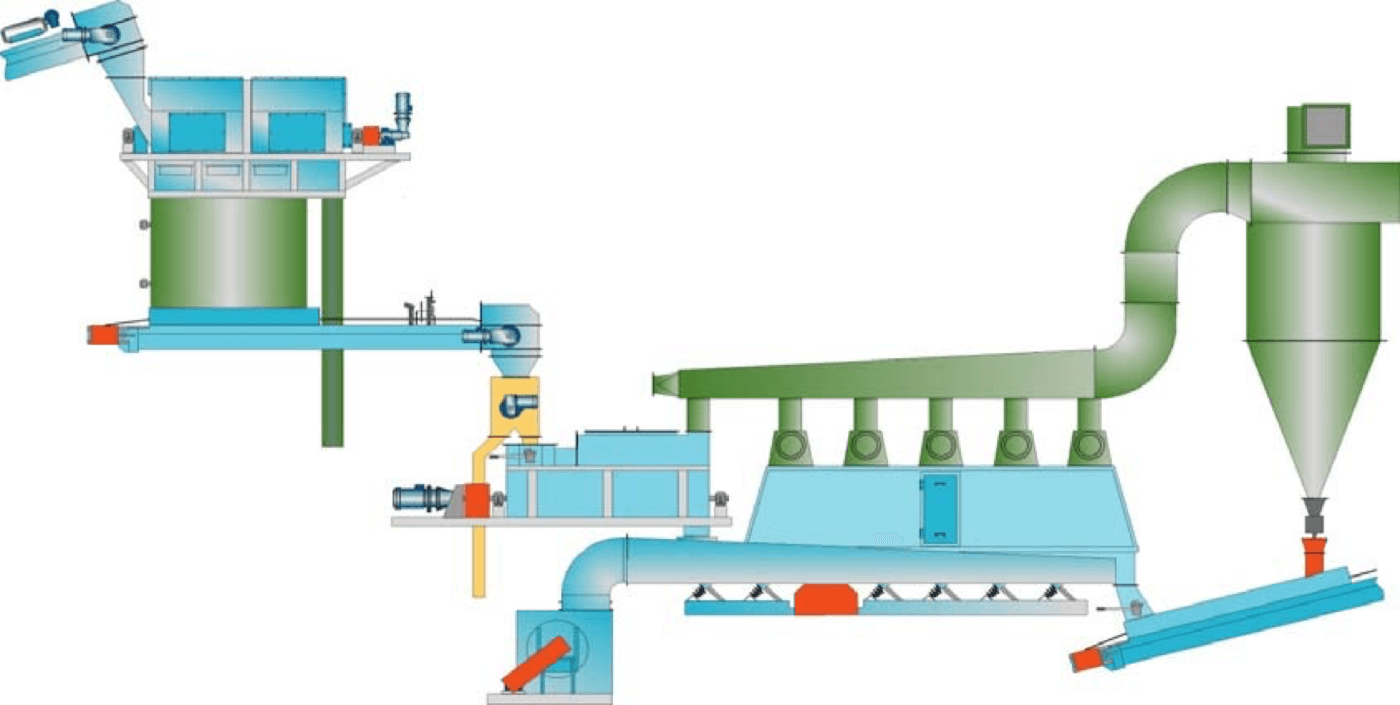

Practically the cooling of the sand is obtained thanks to the water added in the pre-mixer and the evaporation of a certain amount of the same, accelerated by an adequate volume of air passing through the sand in the fluid bed, also the humidity control on the 2÷2,3%, before transferring in silos, promotes the full development of the bentonite

Managing the variability of the physical characteristics of return sand

It is essential to minimize the stopping and restarting of the cooling system , because the constancy of results is more easily maintained if you can always keep the plant in operation, even if the weight of the sand varies .

A hopper, the volume corresponding to 10÷15% of the hourly flow nominal plant, allowing it to absorb and compensate for the high or low peaks, that are always present in the operation of a plant . The hopper is equipped with 3 level . One at the top, should be considered as high-level alarm and emergency and as a result, when activated, stops all upstream machines .

The other two probes are installed at a reasonable height and at a certain distance one from the other. It can be identified as probe of mid-level and low-level.

A guillotine gate valve, motorized and reversible, is installed at the outlet of the hopper and its position is selected and maintained automatically in function of an algorithm that takes into account the time taken to switch from the mid level to the low level and vice versa.

The purpose is to find a position of the gate valve so that the time taken from a position of the mid level to a low and vice versa is as long as possible. This condition means that the flow of the sand in extraction from the buffering hopper corresponds to the incoming flow, then the system operation is practically without interruption.

The search for the position of the guillotine is made by using a self-learning process managed by the PLC.

A tune-up done with care so makes it possible to keep the installation running without interruption, except in the case of important stops of the molding line.

The variation of the flow rate is measured by the weighing system installed on the belt conveyor. In function of the weight of the sand the management software of the PLC adjusts the dosing of the additives in the pre-mixer in accordance with the required values.

The best results are obtained when at the outlet of the cooler is arranged to the installation of the probes to measure the temperature and humidity.

The measured values at the outlet of the fluidized bed are placed in an algorithm that pilot feedback on the dosage of the water added in the pre-mixer and also adjusts the volume of air that is brought into contact with the sand to be cooled.

The device for blowing air through the fluid bed is provided with a by-pass device that directly diverts, into the suction hood, the volume of air that might be in excess in relation to the values of temperature required.

A preliminary calculation of the air volume to be introduced in the cooling system is already determined considering the capacity of the installation and the characteristics of the return sand. While the process is running, according to the physical characteristics of the air itself, it follows a variation of the thermodynamic efficiency which is automatically compensated.

The values found at the exit of the cooler determine the adjustment of the water added and the volume of air accordingly.

The importance of Bentonite for sand quality

The quality of the sand is mostly determined and prepared according to the natural swelling of the bentonite that is activated during the time of rest for the sand in the storage silos. The residence time in the silos should be no less than an hour and a half.

All this of course on condition that shows the values of temperature is around 32÷38 ° C and humidity around 2÷2,3%.

The fact that to obtain the optimal characteristics of the molding sand, in the mixer will have to add only 20÷25% of the total required water, allows to reduce the total cycle time of the mixing and decrease the consumption of additives that could swing between 12÷16%.

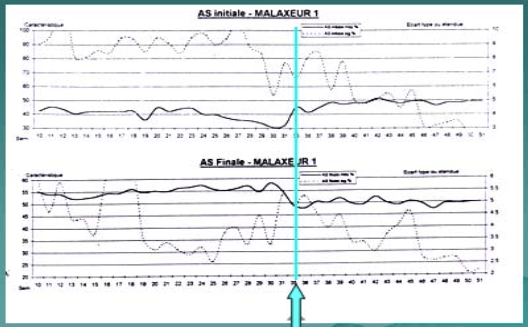

The above graph shows the trend of the compactability of the sand at inlet to the mixer and at the discharge after the mixing cycle. It is clear the difference between before and after use of the plant Space.

It is also confirmed that the sand, well-preconditioned, during the permanence in storage silos acquires spontaneously a value of compactability slightly less than the final value.

This means that all the bentonite has reached its maximum level of efficiency, resulting in a lower consumption.