Benefits after system PGF.4-D installation

- Homogeneous sand moisture at cooler outlet.

- Values of prepared sand moisture inside the strict range required

- Value of compactability of prepared sand inside the strict range required

- Better performance of the moulding machine

- Reduction in sand-related scrap defects.

- Reduction in bad moulds.

- Storage and monitoring of the main operating parameters

When GSM is combined with PGF.4-D

- Management of GSM-L.4, only as analysis instrument

- Enabling the feed-back, on the moisture or compactability values only.

- Enabling the feed-back, also on the dosing of additions.

Description

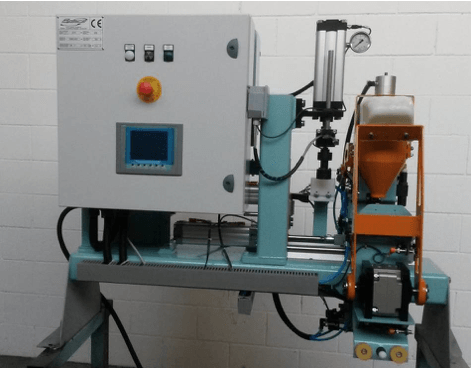

The sampling device has to be mounted on the prepared sand course, so that the sample of sand can be taken at the draw-off belt discharge chute or directly from the belt.

The PGF.4 equipment is already set up for be able to be completed at any time, without any modification, from the GSM tool, for on-line measurement of moisture, temperature, compatibility, resistance to compression and to shear prepared to the mixer output.

On the basis of the measurements performed and the determined values, it provides for the automatic correction of the amount of water and additives to be added into the mixer.

Benefits of GSM Sand Lab

- use in moulding sand processing plants

- eliminates the need to analyze sand in laboratory

Technical drawings

Technical specs

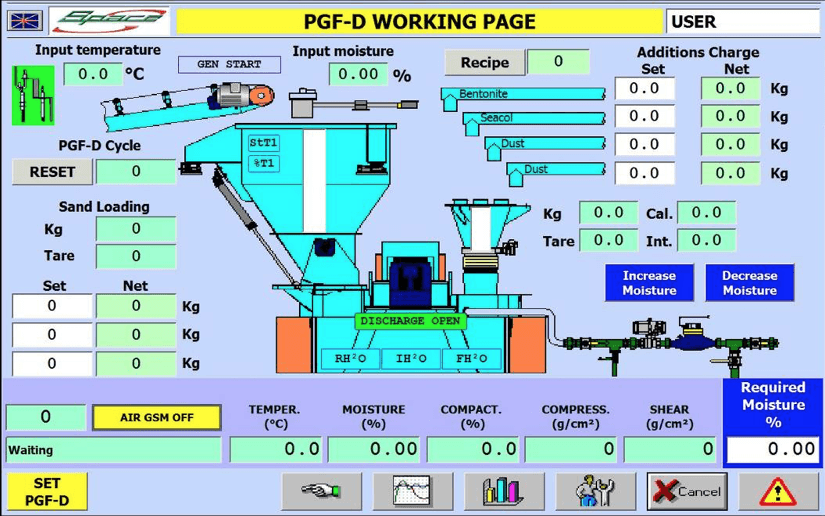

Thanks to the operator panel, the user can program the operating parameters and can check the changes in the values of the system, in real-time.

On the operator panel, the following values are shown:

- Residual moisture of the return sand

- Return sand temperature

- Programmed moisture

- Calculated water flow

- Real water flow introduced

- System alarms in event of anomaly

It is also possible to program and display:

- 3 components for the sand weighing hopper

- 4 components for the addition weighing hopper

Data archive and consumption export on USB key or on PC with Ethernet network and Remote tele-assistance system.

Optional:

- Supervision system and management on the PC.

- Remote operator panel.

Technical specs

| PLC | Siemens o Allen & Bradley | |

| Operator Panel | Touch screen 12” in colours | |

| Main supply | Volt – Hz | 230 – 50 |

| Electric cabinet dimensions | mm | 600 x 600 x 2.100 |

The PGF.4 equipment is already set up for be able to be completed at any time, without any modification, from the GSM tool, for on-line measurement of moisture, temperature, compactability, resistance to compression and to shear prepared to ‘the mixer output. On the basis of the measurements performed and the determined values, it provides for the automatic correction of the amount of water and additives to be added into the mixer.

Technical specifications for the GSM Sand Lab

| Power supply | 24 Volt DC |

| Compressed air supply | 6,5 bars |

| PLC | Siemens o Allen & Bradley |

| Touch Panel | Touch screen 9” |

| Compressed air consumption | 160 Nl/cycle |

| Dimensions (L x W x H) | 1.200 x 550 x 1.200 mm |

| Weight | 330 Kg |

Video

Receive the full technical specification and equipment details for Automatic Management of moulding sand as a PDF document direct to your inbox. Simply provide your email and you will receive the download shortly.