Green Sand, Sand preparation, Sand quality control

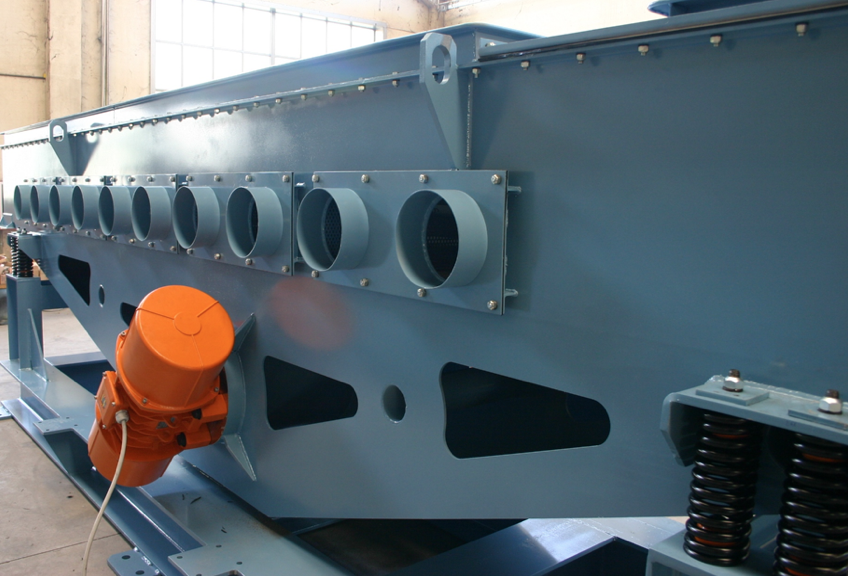

TVR Fluid Bed cooler

Avantages

- Economy of additives up to 10%.

- Reduction of mixer cycle time up to 15%.

- Stabilization of compactability, compression, shear, tensile strength and RHH in prepared sand.

- Reduction in machine maintenance costs.

- Significant reduction of scrap due to the quality of the sand.

- Fluidization bed made up of micro-perforated stainless steel sheet panels, which guarantees a long service life and reduces the risk of sand sticking to the surface.

Caractéristiques de base

- Base sub-frame constructed from a very heavy, all welded steel fabrication.

- Supports the vibrating trough suspended within.

- Trough suspension system with 4 groups of coil springs.

- Structure designed to completely absorb and eliminate vibrations produced by the movement of the vibrating machine.

- Longitudinal bottom chamber, located under the fluid bed trough is made from mild steel plate and subdivided into several separated chambers.

- Chambers are fitted with air inlet spigots, equipped with adjustable butterfly valves.

- Static dust hood, built in stainless steel, which allows the expansion of the cooling air.

Description

The cooling is obtained by the transfer of the calories necessary to produce the evaporation of the water which is dosed and mixed. The evaporation is favoured by the flow of air that passes through the layer of sand homogeneously formed as a result of the oscillating movement of the transport channel.

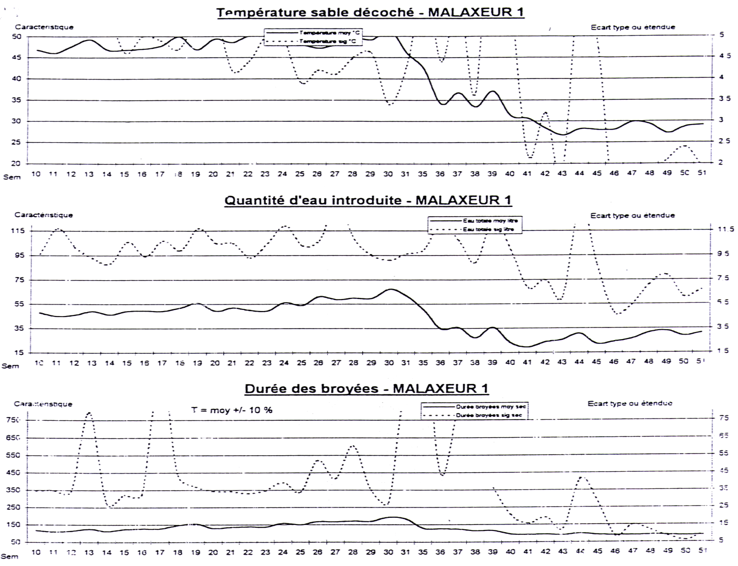

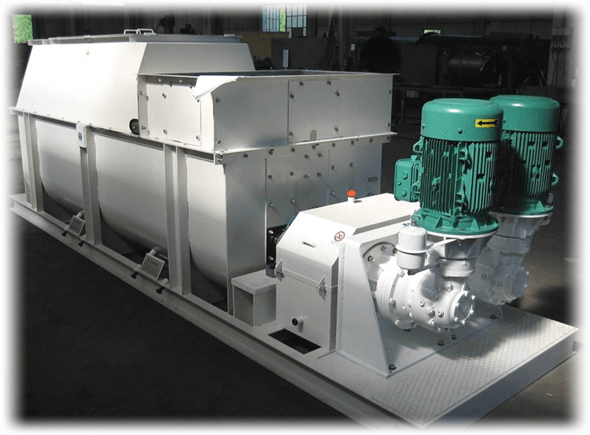

The TVR cooler, coupled with the MU premixer and the PGF controller, provides the best possible performance and guarantees maximum cooling efficiency and sand homogenization.

A well-developed management system allows for the automatic adjustment of air and water volumes according to the weight, temperature and moisture of return sand.

A judiciously installed network of sensors enables the measurement of the main physical parameters. Our processing software calculates and orders the necessary corrective actions

Equipment gallery

Technical drawings

Technical specs

|

Model |

Capacity T/h |

Power supply [kW] |

Voltage [V – Hz] |

Air volume to suck [Nm3/h] |

Fan power supply [kW] |

Dimensions L x l x h [mm] |

Weight [Kg] |

| TVR.500 | 20 ÷ 40 | 2 x 4 | 400 – 50 | 14.500 | 11 | 4900÷5800 x 850 x 3400 | 4.200 |

| TVR.750 | 40 ÷ 70 | 2 x 4 | 400 – 50 | 17.500 | 15 | 4900÷5800 x 1100 x 3450 | 6.200 |

| TVR.1000 | 70 ÷ 120 | 2 x 4,9, | 400 – 50 | 22.500 | 18,5 ÷ 22 | 4900÷7600 x 1350 x 3650 | 8.750 |

| TVR.1250 | 120 ÷ 180 | 2 x 9,2 | 400 – 50 | 26.500 | 30 | 6700÷7600 x 1590 x 3800 | 11.450 |

| TVR.1500 | 180 ÷ 230 | 2 x 9,2 | 400 – 50 | 29.500 | 37 | 6700÷7600 x 1850 x 3900 | 13.450 |

NOTE: The power of the fan and the air sucking capacity are indicative. They are always established according to the actual flow rate and temperature of the inlet sand.