Benefits

- HR steel mesh panels fixed to the frame of the cage

- Modular design allowing for quick change of core elements

- Suitable for new installations and plant renovations

- Reduction in condensation and sand collection inside the screen body

Description

The SPR polygonal rotary screen is a well-proven solution for sieving shake-out green sand. The design of these machines has been treated to render them suitable not only for new installations but also for the renovation of existing plants.

“SPR” units are designed particularly for their use in foundry green sand preparation plants.

The multiple model range of screens covers plants with a capacity from 20 to 300 T/h. The design of the equipment is not only suitable for new installations, but can be easily retro-fitted into older plants.

It has been our experience, over the years, that screens tend to be installed in the most inaccessible part of the sand plant, making inspection and maintenance difficult.

Having this in mind, our unit design is not only for long life, but also to overcome long term problems associated with condensation, and sand sticking to the inside of the screen body.

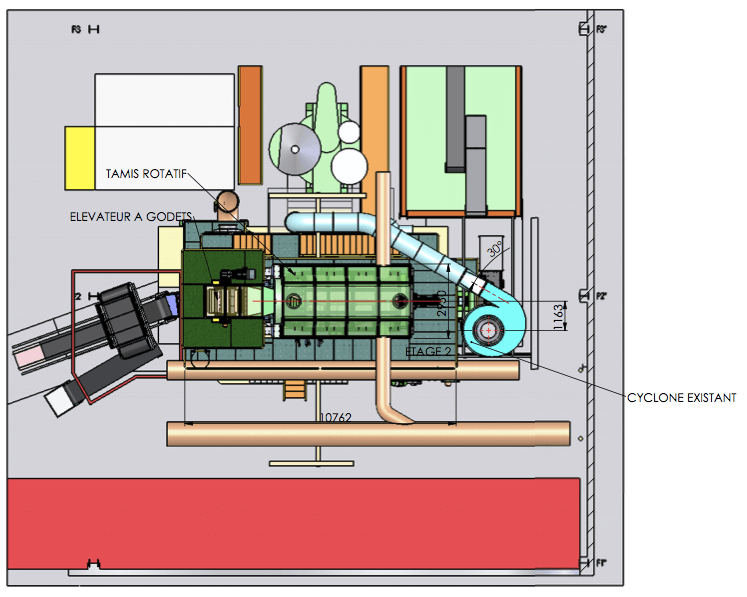

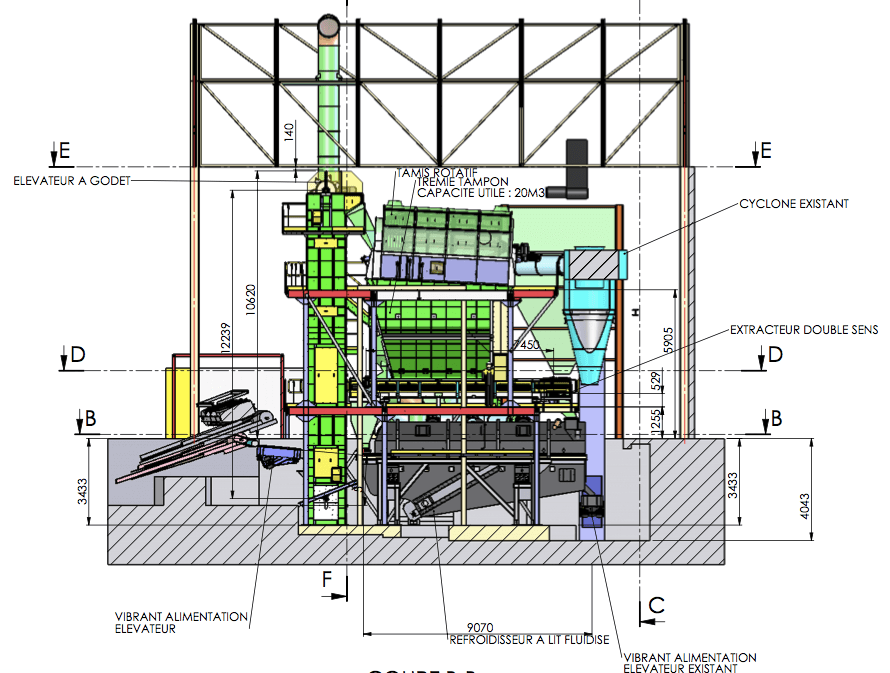

Technical drawings

Technical specs

| Model | Capacity

T/h |

Power supply [kW] | Voltage

[V – Hz] |

Dimensions

L x l x h [mm] |

| SPR.30 | 30 | 4 | 400 – 50 | 3500 x 1600 x 1800 |

| SPR.60 | 60 | 5,5 | 400 – 50 | 4800 x 1960 x 2030 |

| SPR.90 | 90 | 7,5 | 400 – 50 | 4990 x 2300 x 2400 |

| SPR.120 | 120 | 7,5 | 400 – 50 | 5705 x 2300 x 2500 |

| SPR.150 | 140 | 9,2 | 400 – 50 | 5545 x 2900 x 3150 |

| SPR.200 | 200 | 11 | 400 – 50 | 5950 x 2900 x 3150 |

| SPR.300 | 300 | 18,5 | 400 – 50 | 6815 x 2900 x 3150 |