Benefits

- elimination of “free water”

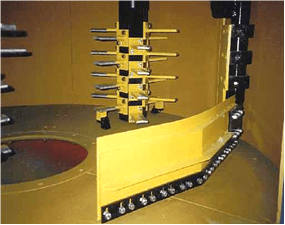

- reloading of mixing tools with special anti-wear products that ensure a long service life

- reduction in bad sand quality-related defects

- helps the spontaneous reactivation of the bentonite

- fewer additive consumptions

- improvement of the casting quality

- optimisation of moulding sand quality

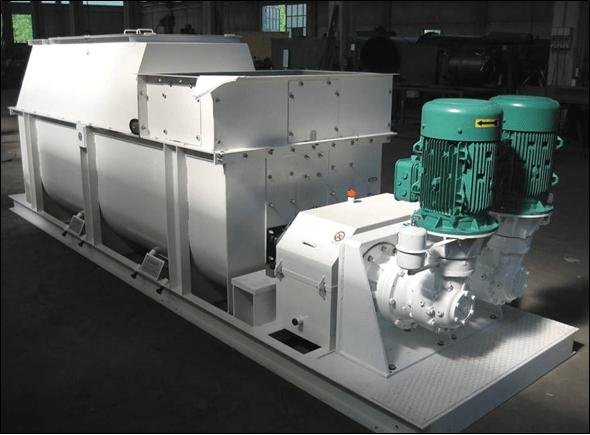

- Robust construction, ensuring a long service life without problems and with minimal maintenance costs.

Core features

- Available from 15 to 250 T/h.

- Safety and accident protection devices

- Distribution of humidification water with special nozzles

- Mixing pan and suction hood made of stainless steel

Description

This type of machine has been specially designed for a homogeneous distribution of water and additives in the return sand, before their storage in the silos, helping the spontaneous reactivation of the bentonite and reducing the consumptions. With the JML SPACE MU, additives are homogenized at best, allowing the improvement of the sand quality.

The uniform distribution of water and additives, before the introduction of sand into the storage silos, facilitates the spontaneous reactivation of the bentonite, while reducing consumption. The wide variations in temperature and moisture of the return sand are at the origin of the difficult control of the sand quality of moulding and almost always lead to excessive consumption additives.

The MU pre-mixer allows maximum use of additives and to optimize the quality of the moulding sand.