VR intensive mixers with rotating bowl

Description

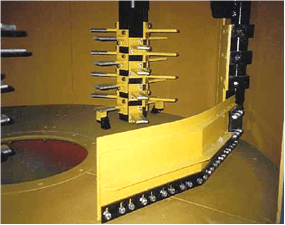

This machine is a rotating pan intensive mixer that, thanks to the combined movement with the turbine and the mixing blades, allows a homogeneous and fast moulding sand preparation, assuring an effective distribution and amalgamation of the additions, a perfect disintegration of clots and a very good sand humidification. Into the pan, the sidewall scraper continuously conveys the material from the periphery to the centre, eliminating dead spaces and keeping perfectly clean the sidewall of the pan. Bottom scrapers, clean the pan bottom (fixed on the turbines and/or the blades).

By filling the mixer, the dry mixing cycle starts, generally short, used for the clot’s disintegration, then, after a fixed time given by the main switchboard, there is the additions introduction and then, trough spray nozzles, the water introduction. Now the wet mixing cycle can start.

At the end of such operation, the discharge door, placed in the centre of the pan, opens and the material falls into the hopper installed under the mixer. After about few seconds, is operated also the discharge blade, which allows a total and more rapid conveyance of residual of material toward the discharge door.

Technical data

Please enter your e-mail address to access the technical data sheet.