The GIFA trade show is the most anticipated event in the calender. JML Industry brought their biggest stand and latest innovations to showcase at this year's event. GIFA 2019 did not disappoint attendees! Despite the sweltering heat it was an incredibly busy show and the JML Industry stand never had a dull moment.

The team dress to impress

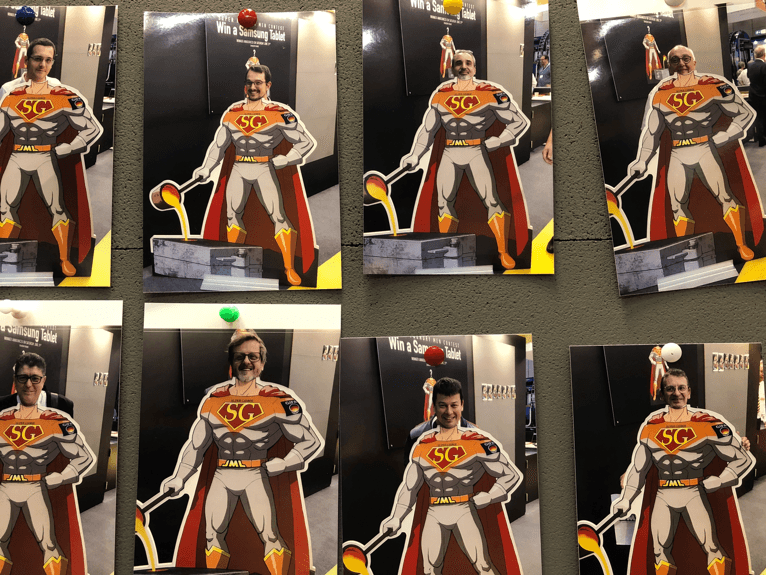

We find Super Foundry Man

Attending GIFA, whilst always valuable, can be exhausting. With so much to see and do, and many evening celebrations, we thought it was important to celebrate just how amazing founders are. This is why GIFA 2019 saw the very first "Super Foundry Man" competition.

We invited stand visitors to have their photograph taken. We had a wall of over 100 foundry men and women by the end of the event. Thanks to all those who took part. It was certainly one of the show highlights.

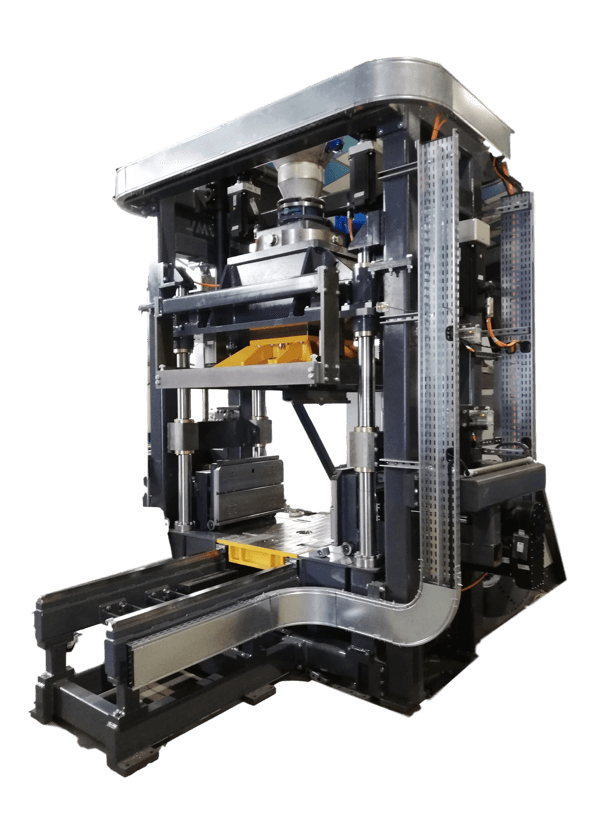

The 100% electric e-shooter is unveiled

The latest innovation to come from JML Italy is the e-shooter. This green core maker is part of the new environmental range of machines launched this year. This clean core-making machine is part of our ongoing commitment to both Industry 4.0 and sustaining the foundry industry environmentally.

The E-shooter can be used either horizontally or vertically, split core boxes and different core box materials depending on the requirements of your foundry. The design of the machine ensures a completely closed core box without movement during shooting and gassing. Installation of the machine can be executed within a week as no pits or foundations are required.

The Rexroth 4EE electric solution is used to deliver a 30% energy saving when compared to a standard hydraulic power unit with vane pump. The energy savings can amount to 383 €/a (404g/kWh, 0.16 €/kWh) as well as a carbon dioxide reduction of 1 t/a.

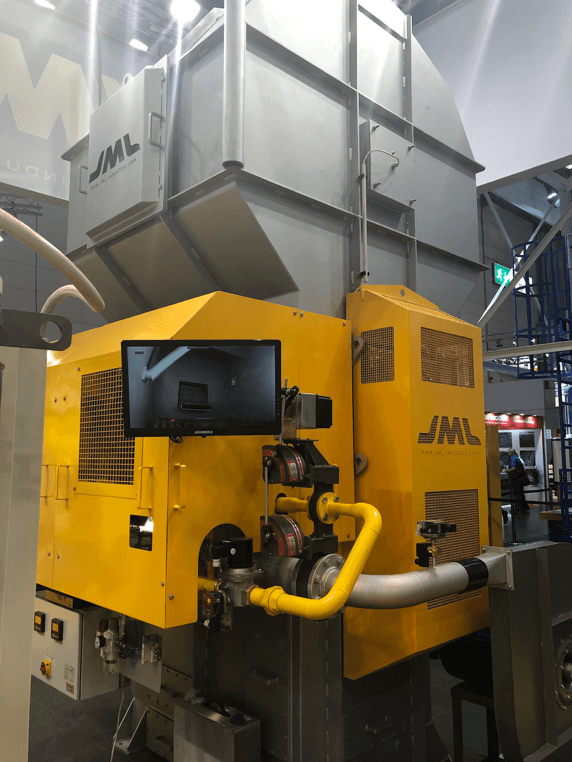

Thermal sand regeneration furnace

One of our newest innovations; the thermal sand regeneration unit, is part of our JML Environment range. We have developed a compact design to help foundries struggling with surface area due to expansion or smaller foundries that struggle with space.

Rather than having a separate combustion chamber and sand-cooling unit, the two have been placed on top of each other. The additional benefit is that the heat generated from the lower sand-cooling unit is used in the combustion chamber, reducing the overall gas consumption.

The compact size and straight-forward compatibility make this particular piece of equipment suitable for foundries of any size.

Regeneration of chemically bound sand is optimised through the removal of all direct contact with flames in the combustion chamber by using two separate tubes after passing on the fluidised bed. Through efficient temperature control the sand exits at a temperature of 30oC. The sand held in the combustion chamber is at 550oC and gases at the top of the chamber are cracked at 850 oC to reduce emissions.

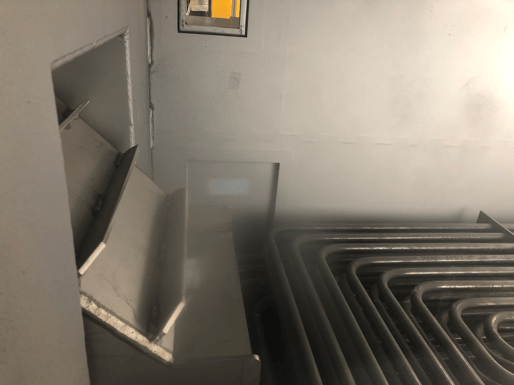

Sand preparation unit

The temperature and humidity of the sand is measured upon entry to the chamber. The integrated calculator then adjusts the water flow to balance the humidity of the sand and temperature on the cooling bed to ensure optimal conditions.

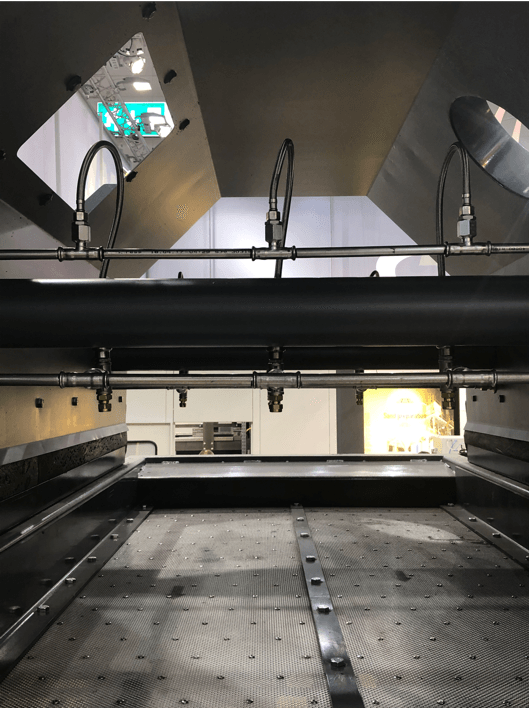

Vibrating technology allows for the smooth transfer of sand from the upper chamber. To assist with standardised cooling and aeration of the sand, there is a constant flow of air underneath our patented grill design.

Our GIFA 2019 stand

This year’s stand was a celebration of the expansion of JML Industrie and of our development over the last 40 years.

During the five-day show we had a full stand each and everyday. GIFA, for JML Industrie, has always been the perfect opportunity to touch base with existing foundry clients and present our industrial equipment to new foundry owners.

This year we saw an increased number of international buyers as JML Industrie continues to grow its global reputation. It is also representative of the expansion of foundries across Eastern Europe and Asia as they develop their practices and invest in European engineering and equipment.