Benefits

- Easy access and reduced maintenance

- High accuracy and repeatability of the catalyser (=/- 1cc)

- Energy efficiency

Core features

- Catalyser dosed quantity display

- Outlet high air temperature (120°C)

- Control of the air pressure profile during gassing and purging

- Catalyser tank cooling (if present)

Description

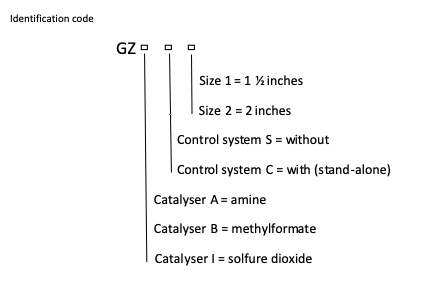

The range of the GZ gas generator has been designed to meet the needs of the modern foundry in which the process control and energy efficiency are fundamental conditions.

The GZ gas generators are compatible with the most common core production processes that use polyurethane-based resins (DMEA, DMIPA, TEA), phenolic-based resins (methylformate) and epoxy-based ones (SO2). Our range of gas generators are produced with or without integrated control system.

All GZ gas generators are CE certified and ATEX 2014/34/UE compliant.

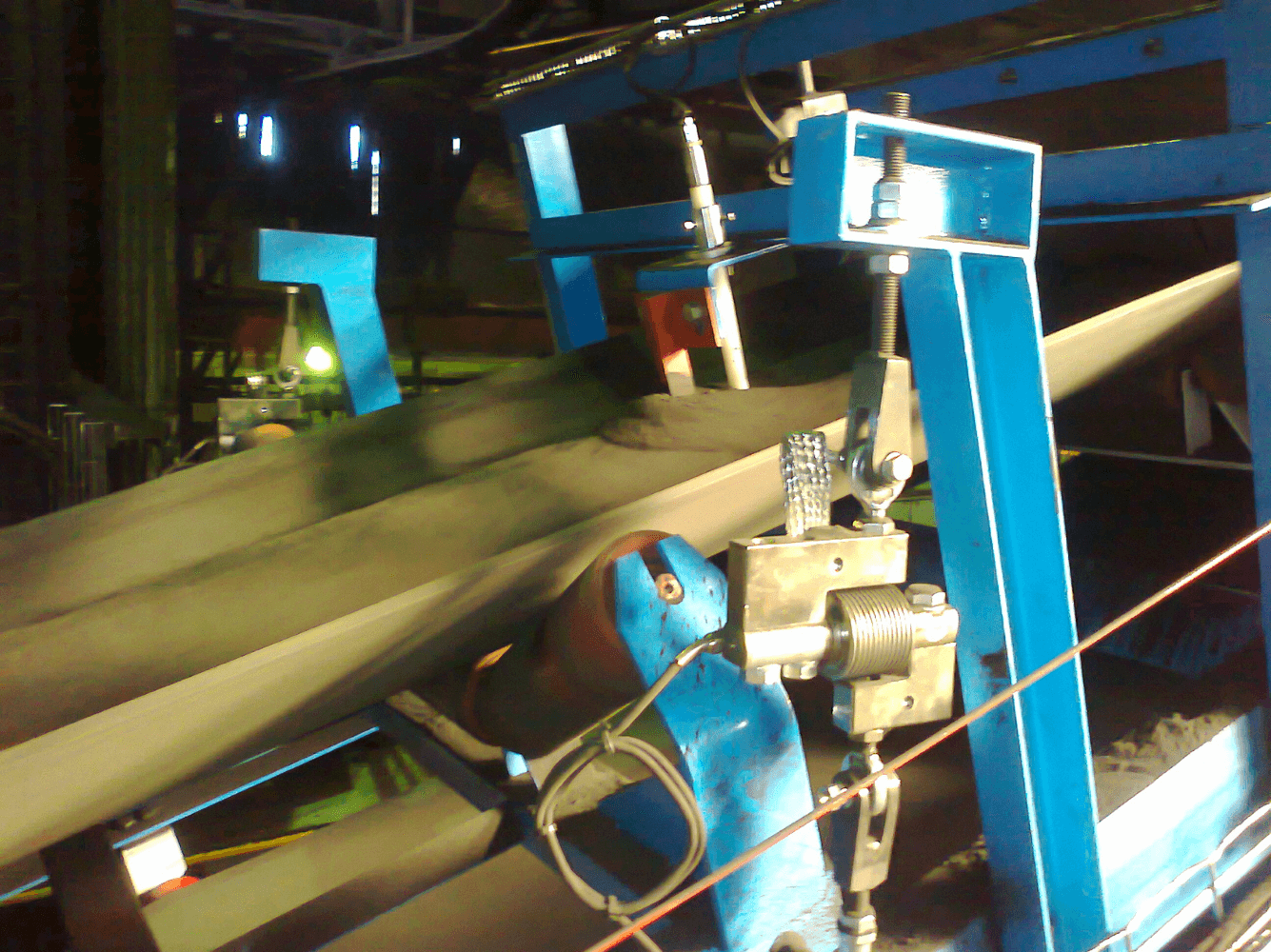

Equipment gallery

Technical drawings

Technical specs

| Model | Power

[kW] |

Voltage

[V] |

Press

[bar] |

Outlet temp

[°C] |

Suction flowrate

[Nm3/h] |

Temp

[°C] |

Tank volume

[dm3] |

Dimensions

[mm] |

Weight

[kg] |

| GZA1 | 12 | 400 | 6 | 120 | 110 | 10-45 | 15 | 950x2000x900 | 450 |

| GZA2 | 22 | 400 | 6 | 120 | 180 | 10-45 | 15 | 950x2500x900 | 500 |

| GZB1 | 18 | 400 | 6 | 120 | 180 | 10-45 | 15 | 950x2000x900 | 450 |

| GZB2 | 30 | 400 | 6 | 120 | 180 | 10-45 | 15 | 950x2500x900 | 500 |

| GZI1 | 15 | 400 | 6 | 120 | — | 10-45 | 2×15 | 1500x2000x1000 | 600 |

The power indicated above shall be increased of 1kW for the standalone models (integrated control system).

Control system

PLC and HMI terminals:

Siemens S7-1200

Siemens KTP-700

Rockwell CompactLogix

Rockwell Panel View 7